Phone

+91 9916322412

Phone

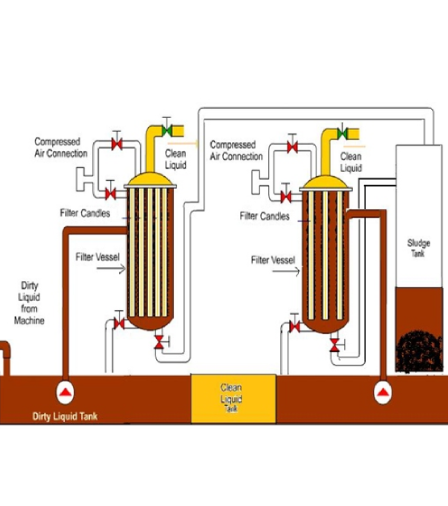

+91 9916322412Contaminated oil is normally introduced through filter vessel & oil flows from the Outer Dia to the Inner Dia of the filter elements, contaminate greater than 1 micron is captured on the outside surfaces of the filter element. When enough contaminant collects on the filter elements & the differential pressure reaches a pre-selected point (^P), the backwash sequence is initiated. This flow pattern assures that all contaminants are collected on the outside of the element for easy cleaning during backwashing. Self-cleaning filters represent the ideal situation & provide the most productive & labor free solution..

The backwash is accomplished by automatically forcing compressed air through them from the Inner Dia to the Outer Dia, contaminate is blown down into a storage container where the oil is drained off. which lasts approximately 180 seconds. There is no introduction of additional fluids to contaminate the process, & the volume of oil discharged is held to a minimum, reducing disposal costs. And then again the drained oil is sent in to the addition Cylinder with 18 filter stick and the same steps is followed it is highly efficient and the results are the life of the Filter sticks are Double the life of the Regular filtration,

| Annual Carbide savings Example | ||

| Reselling value of carbide: | 1400/kg | |

| Machine rate : | 2700/hr | |

| Frequency of cleaning: | 1 mth | |

| Time required for cleaning: | 0.5 Hr | |

| Mug collection/day : | 1kg | |

| Total Carbide saving is the sum of the following: | ||

| Reselling value of carbide: | 1400 | |

| Mug collection/day: | 1kg | |

| No Of Working Days | 30 | |

| Total monthly Carbide savings: | (RV of Carbide * Mug collection/Day *No of Working Days) | 42000 |

| Total Annual Carbide savings : | Mthly Carbide savings * 12 mths | 504000 |

| Lost Productivity on Cleaning /month: | Machine rate*Time required for cleaning | 1350 |

| Total Annual LP: | Lost Productivity on Cleaning /month*12 mths | 16200 |

| Total annual benefit on Carbide | Total Annual Carbide savings -Total Annual LP | 487800 |

| OIL Cost(Super vista Neat cut Oil) 5 barrels: | 28000/barrel | 140000 |

| Frequency of replacing the Oil : | max every 6 mths | |

| Annual Replacement of Oil : | Twice a Year | 2 |

| Total Annual Oil Expenses : | Total OIL Cost *Annual Replacement of Oil | 280000 |

| Total Oil Expenses for 38 mths: | 38 mths / 12 mths * Total Annual Oil Expenses | 886667 |

| Annual Oil Replacement cost saving on 1 micron Filtration | ||

| OIL Cost(Super vista Neat cut Oil) 5 barrels: | 28000/barrel * 5 Barrels | 140000 |

| Frequency of replacing the Oil : | 38 mths | |

| Since no oil replacement required for 38mths Total Oil Expenses remains the same | 140000 | |

| Total cost saving on replacement of oil for 38mths compared with Normal Filtration: | Total Oil Expenses for 38 mths – OIL Cost 5 barrels: | 746667 |

| Annual Wheel Life Expenses | ||

| Expenses on Normal Filtration | ||

| Example | ||

| Cost of a Wheel: | 1000/- | |

| Frequency of Wheel change: | 1mth | |

| Total Annual Expenses on Wheel( Nromal Filtration) | 12 mth / Frequency of Wheel change* Cost of a Wheel | 12000 |

| Expenses on 1 micron Filtration | ||

| Example | ||

| Cost of a Wheel: | 1000/- | |

| Frequency of Wheel change: | Every 3 mths | |

| Total Annual Expenses on Wheel(1 Micron Filtration) | 12 mth / Frequency of Wheel change* Cost of a Wheel | 4000 |

| Total Annual cost saving of Wheel compared with Normal Filtration: | Total Annual Expenses on Wheel( Nromal Filtration)-Total Annual Exp | 8000 |

| Improved Efficiencies on Reduced Cycle times (Based on a nominal 10% overall improvement) | ||

| Reduced Machining Time=Faster Cuts | ||

| Average Work Day: | 24 hours or 1440 minutes | |

| Projected Efficiency | (144 minutes or 2.4 hours): 10% | |

| Machine rate : | 2700/hr | |

| Increased Productivity/ day | Machine rate*Projected Efficiency | 6480 |

| Increased Productivity Monthly | Increased Productivity/ day* No of Working Days | 194400 |

| Increased Productivity Annually | Increased Productivity Monthly * 12 mths | 2332800 |

Apart from the above Cost savings the 1 micron Filtration Systems helps in the Following Reduced Maintenance & Eliminates existing maintenance cost (filters, cartridges, paper rolls)of your machine